Mechanical Engineers shape the world around us and how we live our lives. They invent, design and build things that addresses the problems off today for a better tomorrow.

Mechanical engineering is about putting ideas into action. It is about inventing, designing, developing, manufacturing and maintaining products, equipment and machinery of all kinds. Mechanical engineers use their knowledge of materials, mechanisms, power, energy and manufacturing technology to produce specifications for their designs and to see those designs become a reality. They also build and test prototypes in order to prove their designs.

This course is a result of comprehensive industry engagement defining future needs regionally and nationally. The course will equip learners with the theoretical knowledge and hands-on practical expertise demanded by leading global employers to work in this constantly evolving field.

What will I experience?

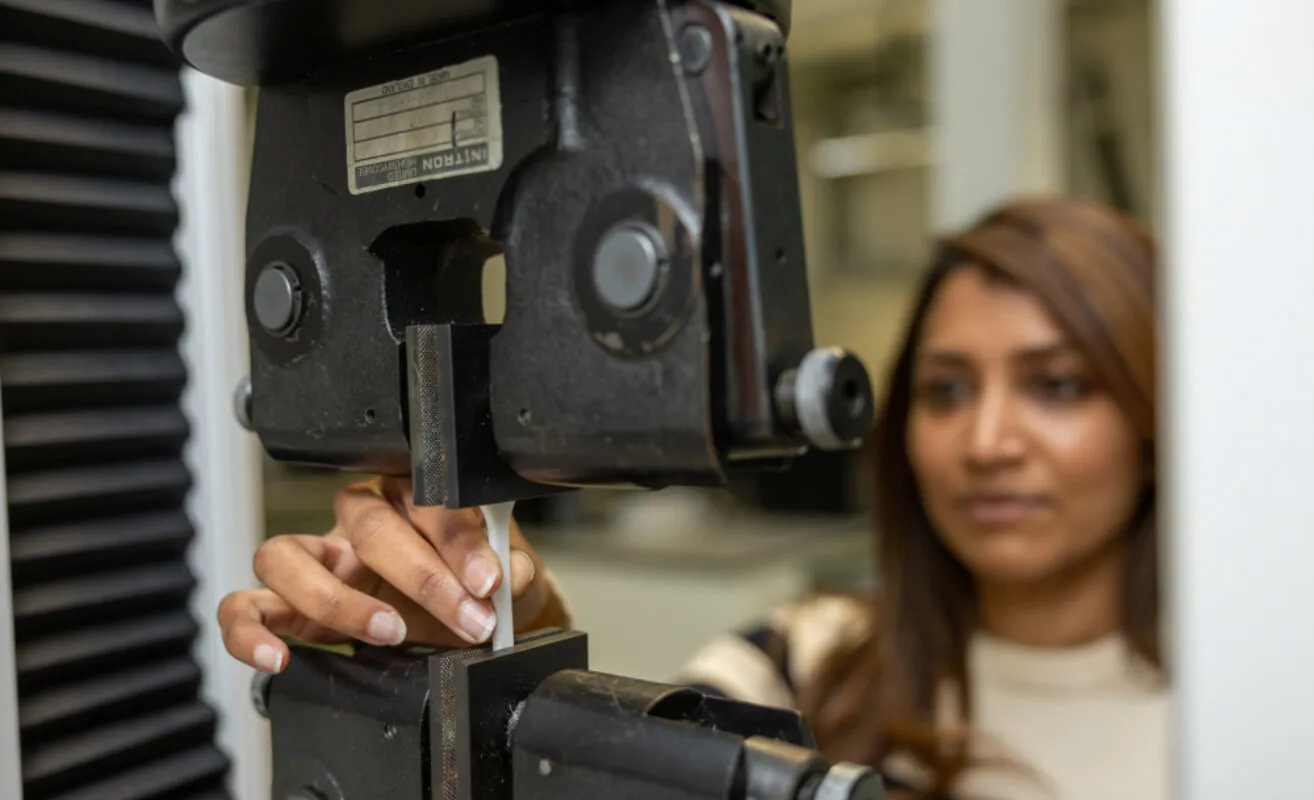

At TUS Midlands, Engineering education is very practical. Almost 50 % of your time will be spent in state-of-the-art laboratories developing your practical engineering skills, and the other 50% will be spent on engineering theory and its application.

While studying on this course students will:

- visit some of our industrial partners to experience the role of a mechanical engineer.

- gain valuable work experience by completing an industry-based project.

- improve their teamwork and communications skills by working as part of small teams on problem-solving and projects.

- develop your problem –solving skills and reasoning techniques.

- work on topic-specific problems, both as part of a team and as an individual and develop your lifelong learning skills.

- develop your ability to effectively communicate within the engineering community and society at large.

- upon completion of the course, will have developed an ability to critically appraise mechanical engineering systems, to identify area of potential improvement, to bring about corrective action and where applicable, to suggest and implement an alternative solution.

- Gain valuable work experience in 3rd year by completing a six month work placement.

In the third year of the course, students undertake a mandatory four-month work placement, which spans from January to April. This placement carries a weight of 25 credits and must adhere to predetermined criteria, mutually agreed upon with the employer beforehand. These placements can be pursued both within Ireland and internationally.

What opportunities might it lead to?

Discussions with leading voices in mechanical and manufacturing domains such as Boston Scientific, Athlone Extrusions and Mergon have expressed theneed for mechanical engineers with practical skills. In designing this course, the TU, engaged with manufacturing and supply chain companies regionally and nationally, who have endorsed the need for this course. Additionally, research-active companies, have all identified the candidate skills developed within this course as necessary for a future workforce.