The honours degree in polymer and mechanical engineering is offered in response to the demand for highly skilled graduates with training in mechanical engineering fundamentals, emphasising specific technologies and methodologies associated with polymer engineering. Polymer engineering is a core skill set that many employers in the medical device/healthcare sector look for in graduates. Ireland’s polymer/medical devices sector is thriving and is recognised as one of the fastest developing in the world. More than 250 companies are currently developing and manufacturing a diverse range of medical devices and diagnostic products. The sector employs a highly skilled workforce – over 45% of employees in the medical device sector are qualified to graduate or postgraduate level.

The student must complete a paid six-month placement from January to June in the programmes third year. The placement carries 25 credits, and most fulfil prescribed criteria, to which the employer will agree in advance. Placements may be done in Ireland or abroad. Placements are readily available across the medical devices, pharmaceutical and broader advanced manufacturing sectors. Companies include Boston Scientific, Medtronic, Harmac, Trend, and Bausch and Lomb.

In this course you will:

Apply core polymer engineering principles to the design and development of polymer products and medical device components.

Have the opportunity to undertake a paid six month placement, commencing January of Year 3. The placement will facilitate you in gaining an insight into industrial practices in your area of specialisation (for example product design, regulatory affairs, polymer processing).

Undertake a final year project, designed to enhance your research and analytical abilities. The project will be organised in co-operation with industry and may in certain circumstances follow on from work initially carried out as part of your work placement.

What will I experience?

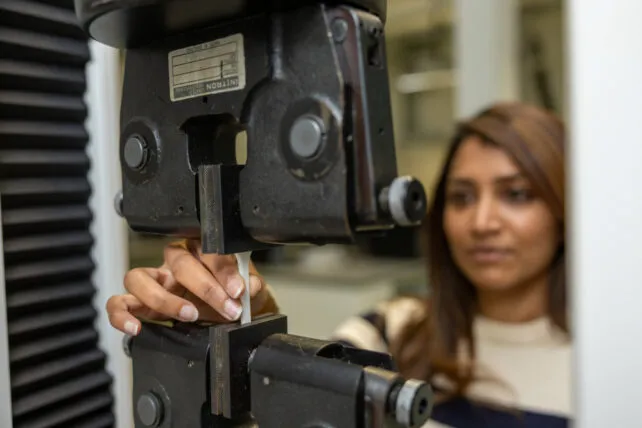

At TUS Midlands, Engineering education is heavily practical based. Approximately 50% of your time will be spent in state-of-the-art laboratories developing your practical engineering skills, and the other 50% will be spent on engineering theory and its application.

While studying on this course students will:

- Visit some of our industrial partners to experience the role of a mechanical engineer.

- Operate high-end technical engineering equipment in our cutting-edge engineering laboratories.

- Develop the ability to critically appraise mechanical engineering systems, to identify area of potential improvement, to bring about corrective action and where applicable, to suggest and implement an alternative solution.

- Learn about the environmental loadings of processes/plants and be committed to their reduction, either in terms of the product, the materials or the process.

- Improve your teamwork and communications skills by working in part of small teams on problem-solving and projects.

- Develop an ethical awareness concerning the engineering profession and environment.

- Gain valuable work experience in 3rd year by completing a paid six month work placement, and in 4th year by industry-based project.